Instead of flushing hundreds of dollars down the toilet, I think it’s wise to make homemade toilet paper at home.

Alternative toilet papers are cost-saving, eco-friendly, and self-reliant. They are like making paper at home with biodegradable materials such as grass, leaves, wood, and recycled paper.

If you haven’t copied it from your neighbors, here is a complete guide to creating homemade toilet paper from accessible materials.

Step-by-Step Guide to Making Toilet Paper from Recycled Paper

Step 1: Gather and Prepare Materials

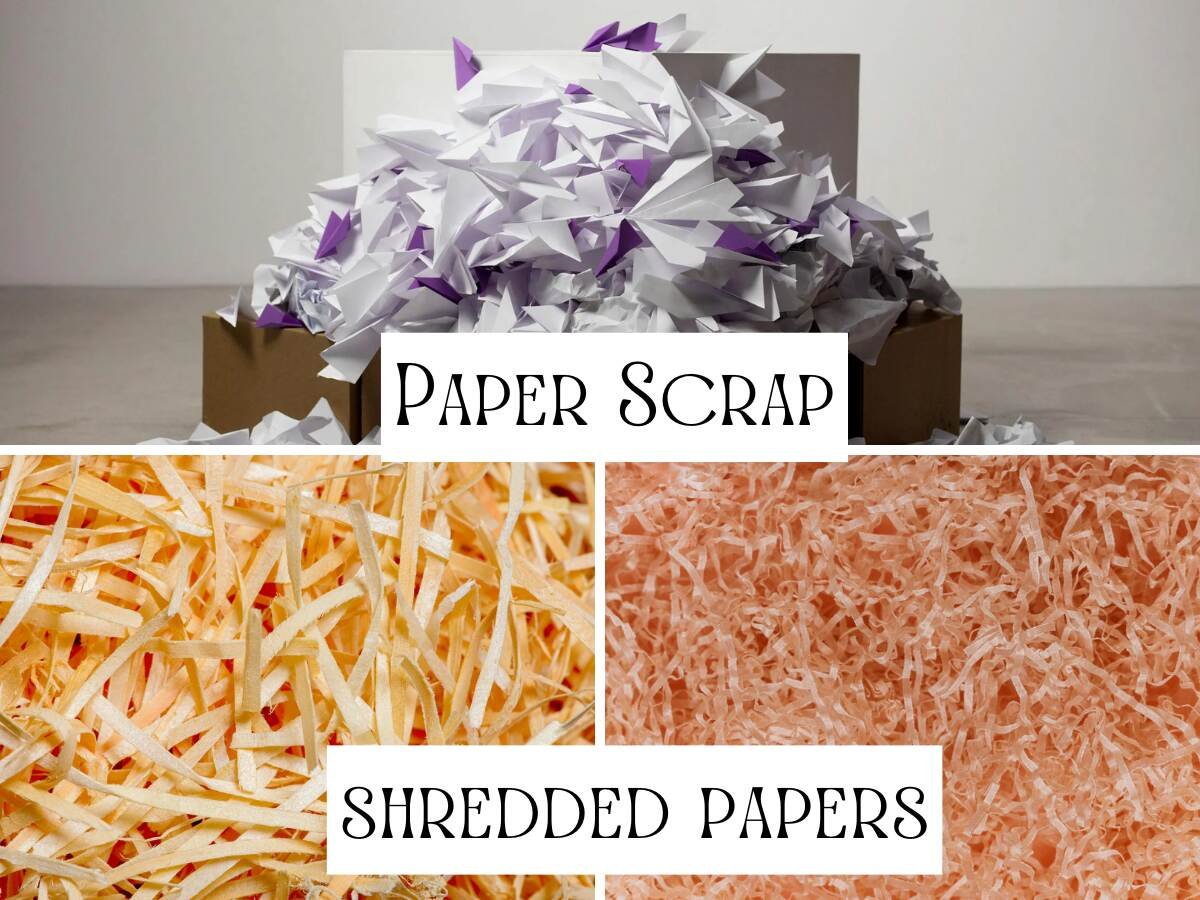

Office paper, computer paper, cardboard, food-contaminated paper, moldy paper, carbon paper, sticky notes, magazines, newspapers, and books are all recyclable.

Gather the old or scrap peppers and tear them into small pieces so that a pile can be managed in a container.

Check the papers have any staples, glue, or non-paper elements, including staples and metal objects. These contaminants can damage the quality of recycled paper toilet paper.

Step 2: Pulp the Paper

After shredding, soak the paper in a large container filled with warm water for 24 hours.

Drain the water and take the soaked paper to a blender. You can also use a driller to make the pulp. Add some fresh water, but don’t spoil it, and start a blender.

Then, filter the large chunks of paper by pouring the blended pulp on a strainer or slotted spoon. Also, drain the fine pulp somehow.

Step 3: Create the Sheets

A floor cover or any flat objects can be used to place the pulp. You can also use a damp towel or fabric cut into one square foot.

Now, spread the paper pulp evenly over a screen or mesh frame, creating a thin sheet, and cover it well.

The pulp has excess moisture, so you need to press it out using a rolling pin or hands. Ensure that the pulp sheet is covered between the two flat surfaces and solid enough to endure the pressure.

Step 4: Dry the Sheets

Place the sheets to air dry completely in a well-ventilated area.

Wait for an overnight! You can also install fans to pace the process. Sun drying and using a low-heat oven are also some alternative drying methods.

Step 5: Cut and Store

Ensuring the sheet is dry completely on both sides, separate the sheet from the frame or fabric.

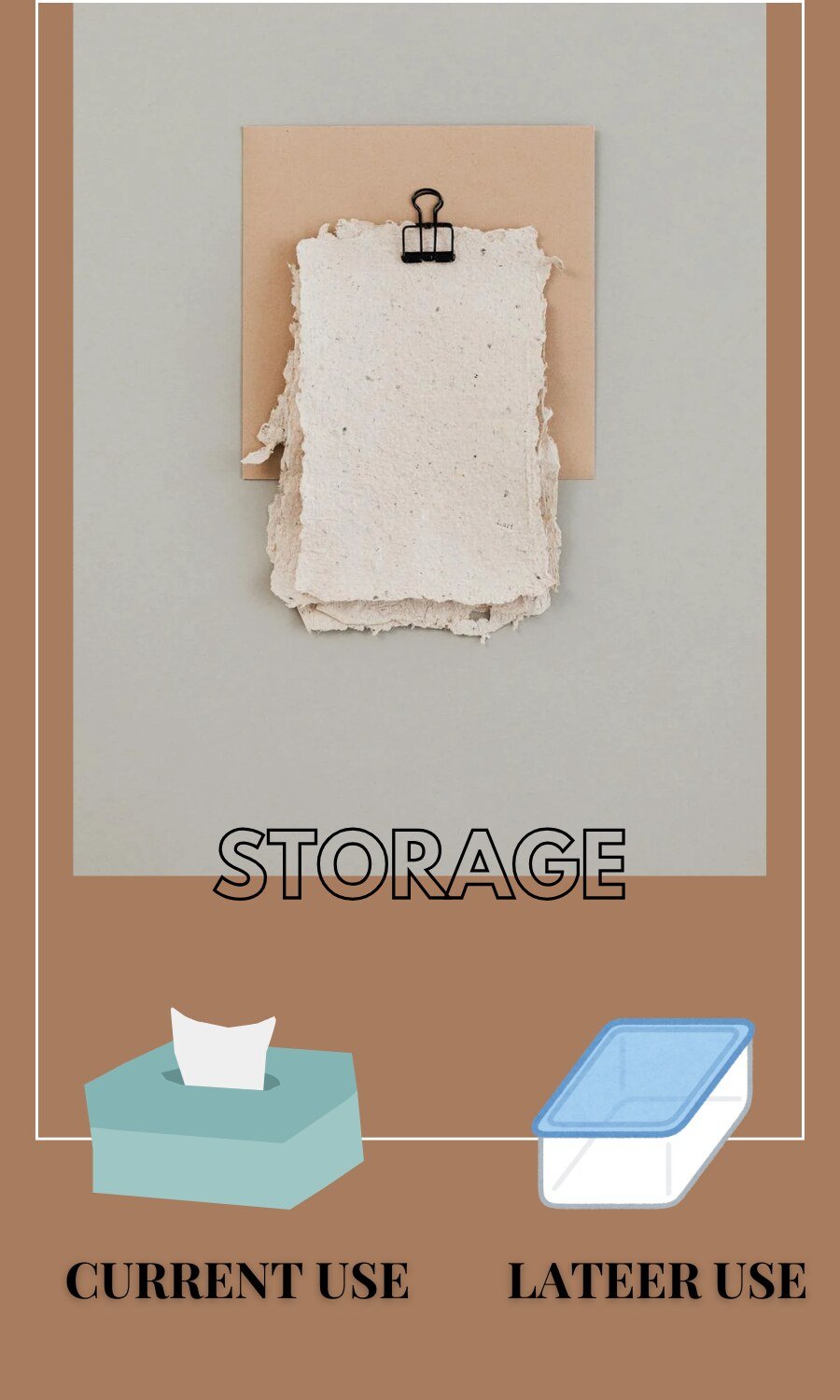

Now, it’s time to cut the dried sheets into usable sizes. 4 inches X 4 inches will be fine. You can make a small pile of homemade toilet paper, insert it into the waterproof bag, and store it in a clean, dry place.

DIY Toilet Paper from Wood

Softwood trees, including firs, pines, and conifers, are the best choices for making alternative toilet paper at home.

Their shaves are easier and dissolve into threads nicely when soaked.

To start, you need to collect wood chips, water, and basic tools, including a draw shave, container, wood plane, vinegar, food processor, two screens to flat surfaces, weight for pressure, and sheets of fabric for cover.

It would be fine if you already have small wood curls. Otherwise, begin with the following:

- Hold a tree log or trunk and remove the bark using a draw shave.

- Then, scour the wood into small chips, rubbing the wood plane. The thinner the chips, the better.

- Put all the wooden pieces into the container with water. Pour the pieces until they float, and add 2 cups of vinegar.

- Let it soak for 24 hours.

- Now drain the wooden curls and fill the food processor with them in 2/3, adding water to reach the top of the curls.

- Start the processor. Add water if needed and restart the machine until you get a slurry.

- Drop the pulp from the processor and drain using the slotted spoon.

- Now, you are free to follow the above-mentioned steps to make toilet paper from recycled paper: sheeting, pressing, drying, and storing.

Wood is a bit tough to make fiber from, so you need to chop it into as small and thin a piece as possible.

Also, you may have to blend the pieces more than once to make a fine pulp. Once the final product arrives, you may find little rough around the edges.

Homemade Toilet Paper from Leaves

Some plant leaves such as lamb’s ear, common mallow, Indian coleus, pink wild pear, large leaf aster, and blue spur flower are natural alternatives to toilet paper.

How dare I not mention the mullein plant, which has the exact nickname toilet paper plant or cowboy toilet paper plant!

Other than these, you can opt for plant leaves that are large, soft, and non-toxic to the skin.

Collect the materials: Fresh or dry leaves, scissors, hot and fresh water, a large bucket, a blender, wooden frames, fabric sheets, a roller or weight for pressure, bat, and a strainer

Cutting and smashing: Cut the leaves into pieces, measuring 1-2 inches. Or smash the dry leaves by beating with the wooden bat.

Soaking: If you already have hot water, put all the leaf stripes into the bucket with hot water. Otherwise, you need to travel to the oven. Allow the stripes to soak overnight.

Pulping: After draining the leaf scraps, blend them in the food processor or any other preferable machine. If not, you have to beat the leaves to pulp manually with a strong bat. Make sure you get fine sludge. Take out the pulp using a strainer.

Couching the pulp: Now, make a sheet of pulp on the fabric piece and cover it with the same or another piece. Place it on the wooden frame and press it with the weight, or run a roller.

Drying and storing: Position the sheet in a well-ventilated area and let it air dry completely. Once done, detach the final product from the fabric. Now, you can cut it to the desired size and store it in a dry, clean, and airtight container for later use.

Alternative Methods for Making Toilet Paper

Other materials, such as bamboo, hemp plants, or cotton cloth, can be transformed into toilet paper.

Also, not to forget the virgin trees, which are a combination of 30% softwood and 70% hardwood.

These natural fibers need the same treatment as mentioned above, starting with extracting the raw materials and shredding them into pieces or curls for pulping, drying, and storage.

If you want to produce toilet paper in large amounts, you can invest in mold, deckle, vat, felts, a press or sponges and brayer, and drying equipment, including dehumidifiers and water extractors.

These tools help you complete the task efficiently.

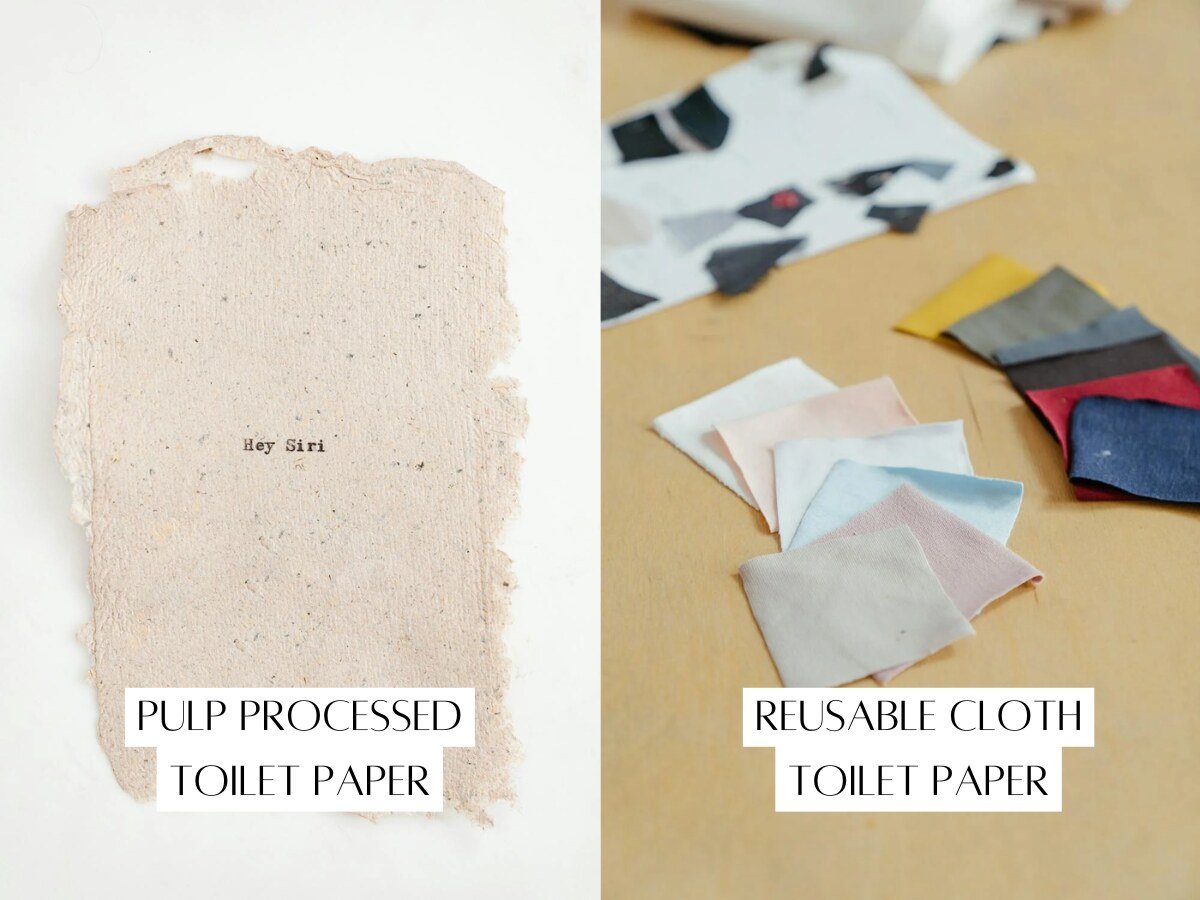

You can also repurpose fabric and make homemade toilet paper.

Reusable family old clothes and clothes that you don’t wear now, made from soft fabrics, can make good alternative toilet paper.

You only need to cut the clothes into pieces, measuring the cardboard toilet paper roll for width.

Keep the length not more than 4-6 inches. You can place the pieces in the bathroom directly now or after completing the cloth edges with a zig-zag stitch on a sewing machine.

Consider placing the cloth strips in the basket or roller next to your toilet.

After wiping, put the cloth into a wet bag or trash bin. On the wash day, dry these reusable clothes under the sun.

Tips for Comfort and Usability

You can improve the quality of your homemade toilet paper processed through pulp.

For example, you can smoothen the texture by using a sandpaper block. After the final product, you can rub the block on the surface of the toilet paper.

Or add natural softeners like aloe vera to the surface before use.

Besides, you can scent your toilet paper naturally using lavender, eucalyptus, or chamomile.

It is also wise to combine some other raw materials without depending on the sole one. For instance, you can mix bamboo and wood or hemp and jute.

This can help improve durability and produce large quantities.

Making Toilet Paper With or Without Machines

I have used only a blender as a machine in making homemade toilet paper at home. If not used, you can make pulp by beating the soaked shreds with the wooden bat and cutting with a big knife.

This way, you can make your own toilet paper at home without a machine.

However, you can make this sanitary tool in large amounts without a proper set of machines. The production will be only enough for individuals or a couple, not more than this.

So you can create a homemade toilet paper machine yourself by setting up the following materials:

- 1 steel pipe

- 1 DC motor

- 1 power switch

- 2 cylindrical wheels

- 1 metal cutter

- 1 saw

- 1 Cardboard

- 3-inch cardboard or plastic tube

- Bolts and nuts

If not, you can buy one for small-scale production, which may cost from $5000 to $10000. This way, you can turn your hobby into a toilet paper business.

Final Thoughts

You need not use glossy or chemically treated paper as they don’t make good pulp. Also, over-blending the pulp can lead to weak sheets.

So, you need to prepare a thick and semiliquid mixture of pulp to make quality homemade toilet paper at home.

Also, many mistake not to dry the sheet thoroughly, leading to mold or mildew.

Leave a Reply